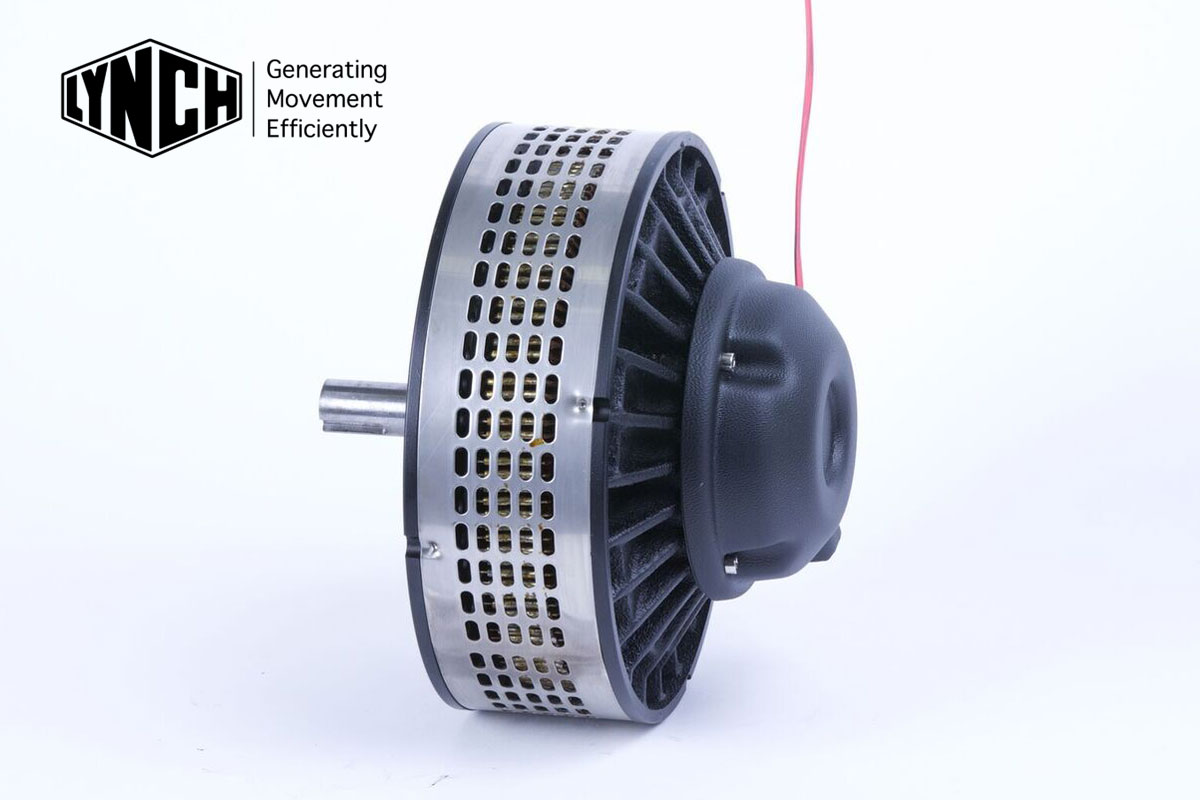

The Racing version of our generator has been developed jointly by LMC and JPS Concept based on feedback gathered over several years, and normal usage fault data for the standard product previously used.

COMPOSITION OF OUR RACING GENERATORS

Specially selected rotor

These components are carefully selected from full production batches for their natural balance to minimise the amount of material to be removed during dynamic balancing.

Rotor strapping

The rotor is strapped around its circumference using a fibreglass/resin strip reinforcement to achieve good dimensional stability over time, despite centrifugal forces, and enable higher rotation speeds.

Reinforced brush holder

G11 fibreglass brush holder instead of the injection moulded brush holder used in the most recent standard models. Aviation-grade locknuts are used in preference to the Nylstop nuts used on standard models to secure and connect brush holders.

High-performance bearing

The double bearing is produced to a higher specification than that used in standard models to achieve a play rating of 150dF.

N44-grade magnets

The magnets used are of a higher specification than those used in standard generators to provide improved temperature resistance.

Standard shaft

Compatible with quick-change micro-V pulleys. We recommend the use of standard shafts and pulleys to facilitate belt changes during maintenance.

SPECIFICATIONS

The functional specifications of the RACING Generator are identical to those of the Standard Generator, with the following exceptions:

→ Individual generating mode test conducted at 42V with a 80A load, with a test report provided for each unit

→ Individual test at 6000 rpm, with a test report provided for each unit

→ The RACING Generator is not designed to run constantly at 6000 rpm

→ However, it is designed to cope with occasional and accidental speeds at this extreme

→ The external diameter of its rotor changes very little over time

→ The stresses imposed on the crimped and soldered connector pins are greatly reduced

MAINTENANCE / UPGRADING (RACING SERVICE)

To ensure optimum reliability, these units should be maintained at least every two years. The maintenance schedule includes:

→ Replacement of the fibreglass strapping, followed by a balance check

→ Replacement of front and rear flanges and magnets

→ Replacement of the bearing

→ Replacement of the shaft

→ Replacement of the brushes

→ Comprehensive on-load test and overspeed test

The same schedule effectively upgrades a Standard version to a RACING version (subject to the initial condition of the Standard version upgraded).

JPS Concept is the sole distributor of LMC RACING generators.

Download the Racing Generator L1 datasheet as a PDF file

Contact us now to discuss your project